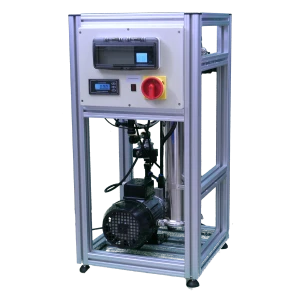

add to wishlist ALFILTRA REOS Pro Max industrial reverse osmosis system

Highlights

Reverse osmosis system as a frame system, low energy input with high yield, fully automatic reverse osmosis system with high-quality control unit installed on a stainless steel frame

Including the following components: Pre-filter 5 micron, safety components such as dry-running protection, fast-flow valve etc., permeate conductivity display, highly efficient membrane system, completely pre-assembled, ready for commissioning.

Description

Reverse osmosis system as a frame system

- low energy input with high yield

- fully automatic reverse osmosis system with high-quality control unit

- installed on a stainless steel frame

Including the following components:

- Pre-filter 5 micron

- Safety components such as dry running protection, fast flow valve etc.,

- Permeate conductivity display

- Highly efficient membrane system

- Completely pre-assembled, ready for commissioning

SYSTEM EQUIPMENT:

The systems listed are compact systems designed as frame devices.

The systems are equipped with a 5micro fine filter as standard. Additional pre-processing steps such as softening, antiscalant dosing, multi media filtration etc. would also have to be taken into account. If the feed parameters change or the operating parameters are changed, the performance data will change.

SYSTEM PERFORMANCE:

The membrane systems are designed for an inlet temperature of 12°C and an inlet pressure of 2 bar. If the temperature of the raw water changes by +/- 1°C, the amount of permeate changes by +/- 3% under otherwise identical conditions. The temperature range for these possible performance changes should not fall below or exceed 8° - 20°C. The membrane system is designed to operate for 3 years.

OPERATING CONDITIONS

Temperature range: 5 – 40°C

pH range: 2 – 11 during operation 1 – 12 during cleaning

SDI / Colloid Index: < 3

Inlet pressure: min. 2 bar – max. 6 bar

Permeate counter pressure: max. 0.3 bar during standstill

Cl2 (free chlorine) < 0.1 mg/l

Scaling must be avoided through appropriate pre-processing measures

Further operating conditions can be found in the 'Mandatory operating conditions for reverse osmosis systems

TCI 110.08' listed.

MAINTENANCE

The reverse osmosis system should be maintained preventively. If the normalized permeate amount decreases by 10%, the differential pressure across the membrane system increases by 20% or the normalized permeate conductivity increases by 15%, cleaning should be carried out. In the event of a longer system shutdown, the membranes must be preserved (see TCL 111.08 Preservation of membrane systems). If you require additional information, please contact our experts.

Attachments (2)

Technical specifications

| ALFILTRA REOS Pro Max 3000M | ALFILTRA REOS Pro Max 4000M | ALFILTRA REOS Pro Max 5000M | ALFILTRA REOS Pro Max 10000L | ALFILTRA REOS Pro Max 20000L | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| sku | 310.RO-M3000 | 310.RO-M4000 | 310.RO-M5000 | 310.RO-L 10000 | 310.RO-L 20000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Manufacturer | FILTRASELECT | FILTRASELECT | FILTRASELECT | FILTRASELECT | FILTRASELECT | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Guarantee | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Operating temperature (min) | 5 °C | 5 °C | 5 °C | 5 °C | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Operating temperature (Max) | 30° C | 30° C | 30° C | 30° C | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Operating pressure (min) | 1,0 bar | 1,0 bar | 1,0 bar | 1,0 bar | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Operating pressure (Max) | 3,0 bar | 3,0 bar | 3,0 bar | 3,0 bar | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Width | 900 mm | 900 mm | 900 mm | 1100 mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| depth | 3600 mm | 2800 mm | 3800 mm | 4800 mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Height | 1850 mm | 1850 mm | 2100 mm | 2100 mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Nominal flow (max. flow) | 3,0 m³/h | 4,0 m³/h | 5,0 m³/h | 10,0 m³/h | 20,0 m³/h | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Categories |

Steam boiler

Reverse osmosis systems |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Osmosis water in the aquarium/aquarium sector

Osmosis water in the aquarium/aquarium sector Ultrapure water treatment

Ultrapure water treatment Microfiltration, ultrafiltration, nanofiltration and reverse osmosis

Microfiltration, ultrafiltration, nanofiltration and reverse osmosis The yield of a reverse osmosis system

The yield of a reverse osmosis system Reverse osmosis: the principle of operation

Reverse osmosis: the principle of operation Advantages of reverse osmosis

Advantages of reverse osmosis für den Privatgebrauch

für den Privatgebrauch

für Industrie und Gewerbe

für Industrie und Gewerbe

Plug & Play complete systems with softening

Plug & Play complete systems with softening

Zubehör für Osmoseanlagen

Zubehör für Osmoseanlagen

Water treatment

Water treatment